Auto Die Cast (India) that sells under the brand ADC always tops the list when searching for one of the trusted Electric Vehicle Parts Manufacturers in Delhi.

Experts in die-casting manufacturing use modern technologies to produce metal components by pushing molten metal into high-pressure strong cases. This technique helps various sectors to acquire durable and precise components faster. Thus, if you require trustworthy pressure die casting manufacturers, especially in India, knowing how, what and why they do what they do will assist you in making the right choice. Auto Die Cast differentiates itself by positively impacting its customers and businesses every single day.

Pressure die casting offers the optimal solution for the efficient mass production of identical metal parts. Consider situations where quick and reliable manufacture of precise and uniform component parts for vehicles and machinery is imperative. Such components highly value the quality of production and the speed of the production end. Pressure die casting employs liquified aluminum or zinc metal, subsequently high-pressure injected into a solenoid-configured fatal. Once the liquified metal solidifies and cools, the resultant component is non-defectively completed. For any industry, large or small, Auto Die Cast offers axiomatically strong, consistently high quality, experience-based products.

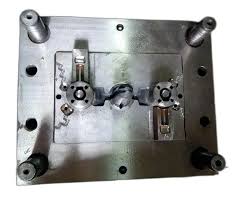

Pressure die casting can be defined as a way of making metal parts under pressure into molds. Die casters start by making a mold made of hardened steel which is a perfect copy of the part needed. Then, the die casters fill the mold with metal which is preheated to above its melting point. After the metal cools to room temperature, the mold is taken off to reveal new part. This process is highly effective as it allows die casters to make thousands of identical parts. This process is preferred by businesses due to the high quality of the end product. Distributing die casting services is a preferred by many businesses since it is a guarantee that all products produced will be identical, precise, and of great quality.

One step at a time, let us walk through the procedure.

This is how Auto Die Cast meets the industry standards for quick, cheap, and strong orders.

Pressure die casting is well known for making strong and reliable die castings across various applications. Its main attributes include:

Automotive, electrical and machinery industries are provided with excellent customer service and product attributes.

Auto Die Cast understands that customer requirements vary greatly, from small businesses needing 1,000 parts, to big factories needing tens of thousands. Their commitment to quality products, quick turnaround, and customer service, sets them apart. Thanks to modern equipment, skilled workers, and dedication to meeting customers’ needs, Auto Die Cast guarantees that you will receive fully custom products exactly to your specification, and will deliver them on time. They have the expertise to work with almost any industry, from the automotive segment to electronics, guaranteeing to be the best choice for any die casting project.

Companies are growing because they are receiving accurate, strong, and reliable metal parts from pressure die casting manufacturers. Experts like Auto Die Cast help avoid issues, provide better quality, and deliver parts faster. To get a quote or learn more about your project, contact the Auto Die Cast employees or visit the company’s website. Auto Die Cast is ready to help you succeed; experience the difference precision engineering and quality service makes!

Q1. What are pressure die casting manufacturers?

Metal parts are made by pressure die casting manufacturers by injecting molten metal into steel casts. Such suppliers are parts manufacturers in the automotive, machinery, home appliances, and electronics industries.

Q2. What are the die casting alloys?

Aluminum, zinc, and magnesium are the alloys most commonly used. The aluminum part is selected depending on the strength and weight, and the application of the part.

Q3. Why should I choose pressure die casting for my parts?

Pressure die casting is more economical for producing large quantities of the same components. Also, it results in components having finer detail, smooth surfaces, and is an excellent choice for components requiring high strength and accuracy.

Q4. How can I make sure my parts are high quality?

A pressure die casting manufacturers with quality assurance, experienced operators, and state-of-the-art equipment is ideal, and Auto Die Cast is a company providing multiple on-the-spot process quality inspections with comprehensive batch quality control systems.

Q5. Is pressure die casting expensive?

While the initial investment for tooling is high, it becomes more economical the more parts are produced, thus it is the most economical for large production runs.

Q6. What’s the difference between high and low pressure die casting?

High pressure is used for smaller, precise, and or more detailed parts while low pressure is better for bigger and less detailed ones. Manufacturers can assist you in selecting the appropriate type for your needs.

Q7. Can Auto Die Cast handle urgent or big orders?

Certainly! Given the state-of-the-art facilities and the extensive experience of Auto Die Cast, urgent orders as well as larger quantities can be handled in a dependable and effective manner.

Choosing the right pressure die casting partner can all the difference for your business. Contact Auto Die Cast and get the experience you can trust!

Enquire Now

Copyright © 2026 Auto Die Cast (India)