Auto Die Cast (India) that sells under the brand ADC always tops the list when searching for one of the trusted Electric Vehicle Parts Manufacturers in Delhi.

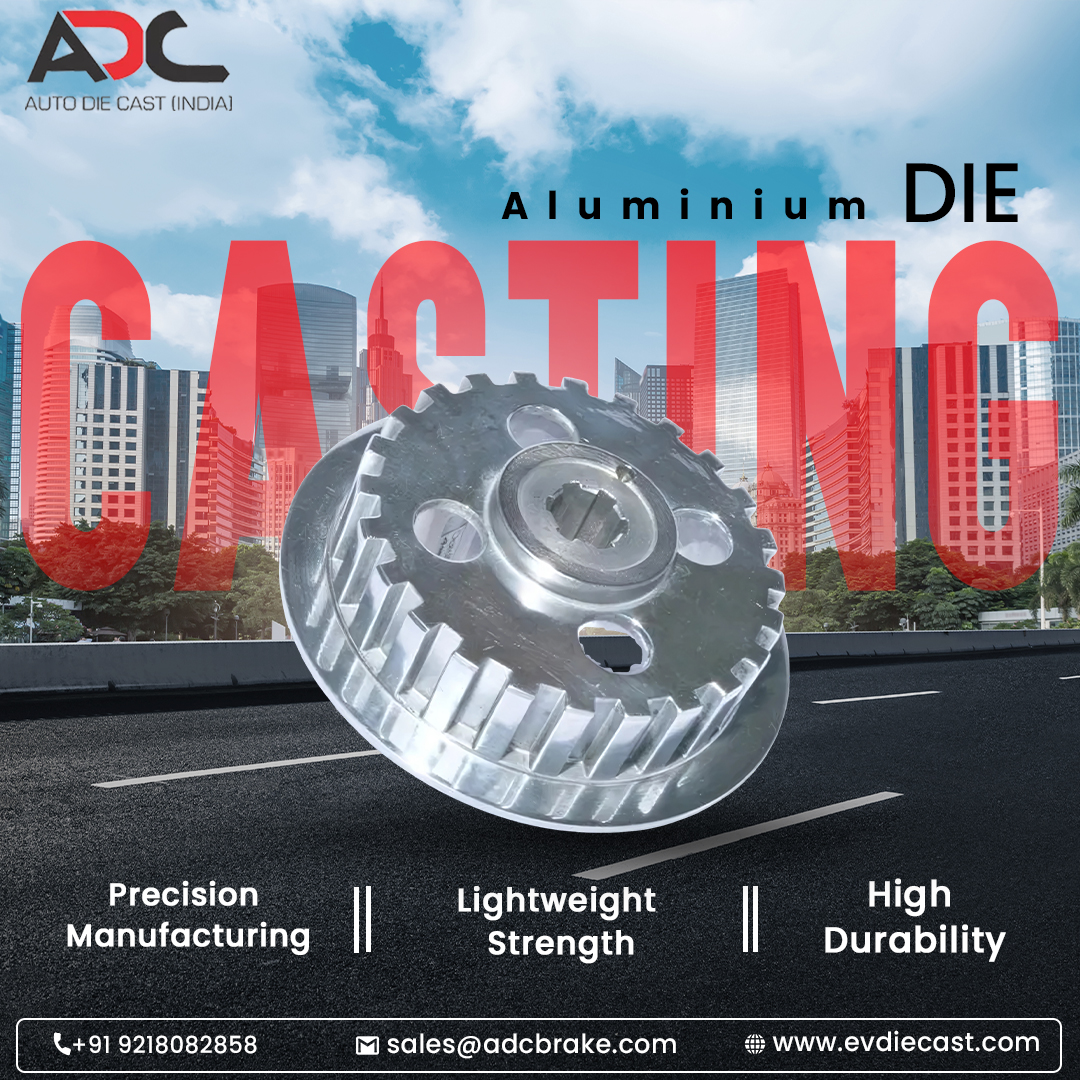

Aluminum die casting has gained popularity due to its ability to produce intricate metal components with high accuracy and longevity. It helps generate a wide range of industrial and commercial items, including automotive components and electronic housings. It involves injecting molten aluminum into a mold to create solid, lightweight, and durable shapes. For industries that need quick turnaround time combined with consistent production quality, aluminum die casting serves this need expertly. One of the trusted names in the field, Auto Die Cast (India), continues to set the benchmark in quality aluminum die casting services.

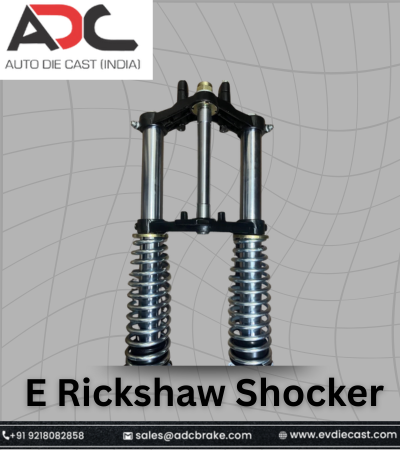

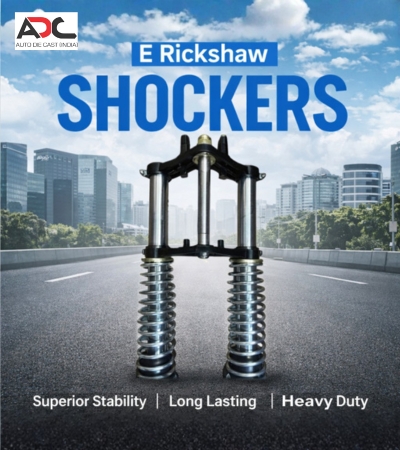

E Rickshaw Shocker makes rides smooth, safe, and long-lasting. Auto Die Cast (India) provides strong shockers for rough Indian roads, keeping passengers comfortable and protecting the rickshaw from damage.

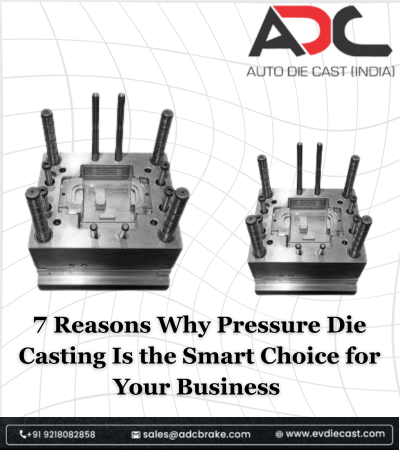

Pressure Die Casting is the smart choice for businesses. It helps make accurate, strong, and cost-effective parts quickly. Many industries trust it for durability, speed, and eco-friendly production.

Electric vehicles are steadily revolutionizing urban mobility. Most notably, E Rickshaws are helping with this transition by being a simple, E Rickshaws are cheap, and uncomplicated solution for urban mobility. They also mitigate pollution. However, with these benefits, new challenges are emerging, notably problems people are calling the E Rickshaw Shocker.

E Rickshaws are functioning by exhibiting a combination of the following problems: short circuits, battery fires, and sudden breakdowns. Such issues raise concerns over the safety of these electric vehicles. Through this blog, we will explore the implications of the E Rickshaw Shocker on a transformative urban transport and the work being done by firms such as Auto Die Cast to the exploding problems.

Within the aerospace sector, the capacity of aluminium die casting to rapidly manufacture robust and lightweight components provides the sector with the much-needed flexibility. Aerospace manufacturers focus primarily on extreme strength and light weight of the material during component manufacturing to ensure optimal performance, safety and fuel efficiency of the aircraft. The following sections of this blog will focus on the applications of aluminium die casting within the aerospace sector and its significance with relation to the aforementioned most applications of precision die casting in the aerospace industry.

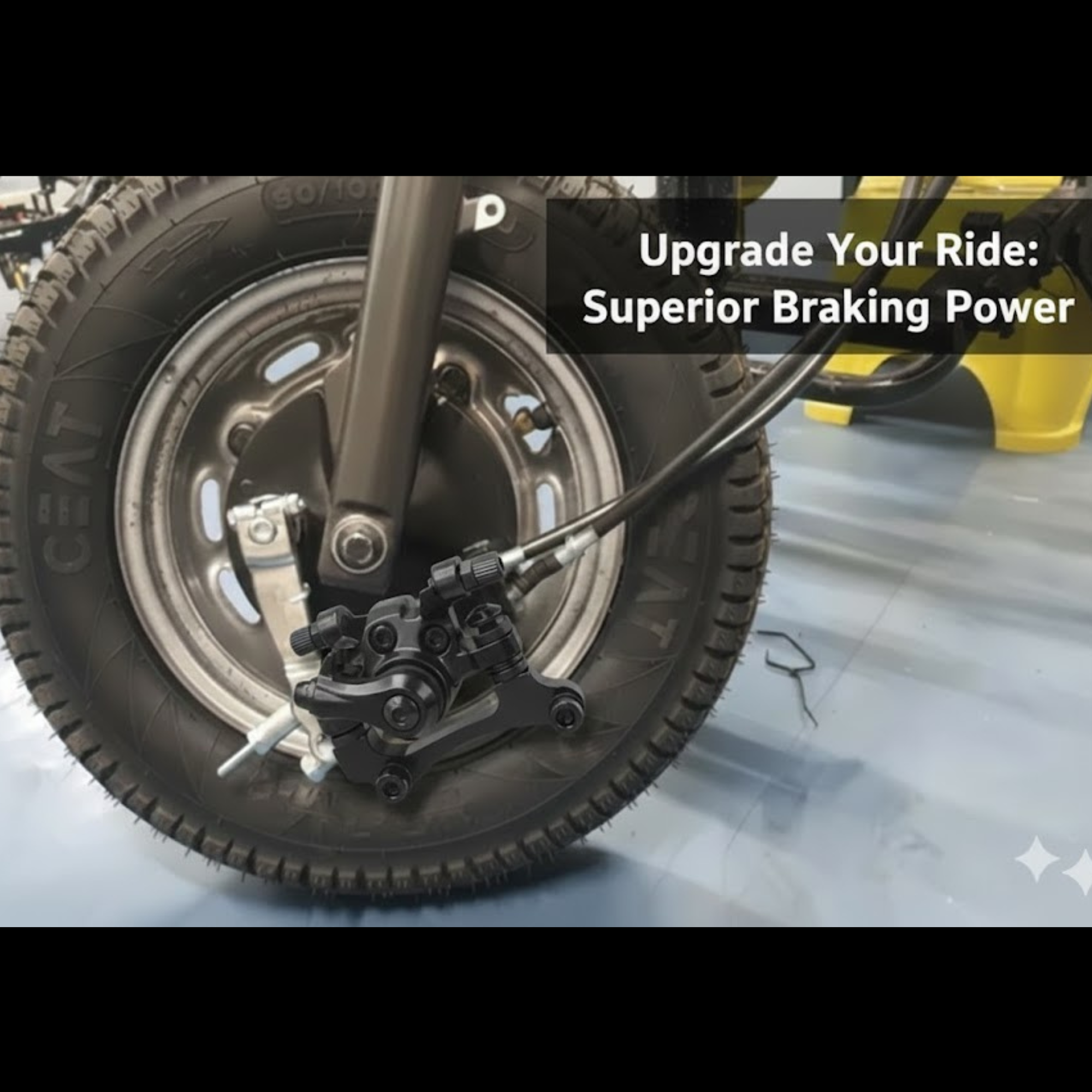

No two-wheeler operational elements exceed the priority of the rider’s safety. The safety of the ride on a scooter or motorcycle hinges on the brakes. Compounded integrated Combi-Linked Brake Systems (CBS) automated modern motorcycle wheel brakes. The system boosts the rider’s safety during halting. Especially during emergencies, the confidence of the rider is boosted safely and rider confidence, more especially during emergencies.

Electric scooters are one of the most convenient modes of transport for short trips. They are easy to use, affordable, and friendly to the environment. Nonetheless, for electric scooters to operate optimally, the most determining factor is the wheels. A good wheel makes the ride smoother, safer, and more enjoyable. That is what the Electric Scooter Alloy Wheel offers—the ideal combination of admired strength, style, and performance.

Performance is not limited to the functional capability of the wheels. Most riders overlook the performance aspect of the alloy. They are easy to lift and durable, specially made with advanced technology like Pressure Die Casting, and focused on the rider’s safety. Pioneers like Auto Die Cast are leaders of performance alloy wheels and have strengthened high-performance electric scooters available today.

There is constant effort from the makers of precision instruments towards the efficient, high-quality manufacture of metallic parts with commendable structural integrity. One of the methods for realizing this objective is the Pressure Die Casting.

The technology is applicable in several sectors, including automotive, electronics and, specifically, alloy wheel and component manufacture for electric scooters. In this scenario, customers require no or minimal post-processing because high-pressure injection of molten metal into a closed die significantly shapes the part. This technology is advantageous in the efficient use of resources in terms of both time and material.

Pressure die casting excels at high volume production. It is completely automated making it possible to create a rapid production of identical parts, perfect for vehicles that are produced at a large scale.

The auto industry is always evolving, and there is a constant drive to make lighter vehicles as well as improved fuel efficiency and new designs. In today's competitive market manufacturing methods are required by manufacturers that are cost-effective, efficient and provide high-quality products. This is why we utilize the pressure casting process, which is a revolutionary technology which has become an essential tool to ensure automotive achievement.

Aluminum die casting manufacturers are companies that manufacture aluminum die cast parts for their customers; the end users vary from industries to consumers, and everyone in between! Those are just a few items that can include aluminium die casting components, where they are absolutely critical. Providing high quality and dependability for those who seek value in precision, Auto Die Cast is a name you can rely on.

Experts in die-casting manufacturing use modern technologies to produce metal components by pushing molten metal into high-pressure strong cases. This technique helps various sectors to acquire durable and precise components faster. Thus, if you require trustworthy pressure die casting manufacturers, especially in India, knowing how, what and why they do what they do will assist you in making the right choice. Auto Die Cast differentiates itself by positively impacting its customers and businesses every single day.

Take a look around you. Whether it’s the car you drive or the smartphone you use, many of the lightweight, complex, and highly durable metal components you encounter were made using a highly sophisticated manufacturing method called aluminum die casting. It is almost akin to a modernized waffle maker, but instead of pouring batter, molten metal is used. The perfectly shaped metal components that result are critical to the infrastructure of modern manufacturing.

People know Auto Die Cast (India) as one of the best E-Rickshaw Shocker Manufacturers in the country and as one of the best producers of dependable, long-lasting, and effective shockers that are provided to e-rickshaw owners around the nation. Since we are committed to quality and innovation, we have been producing shockers that promote better comfort during rides and increase the lifespan of the vehicles. Each shocker is manufactured by a specialist team that utilizes the most modern aluminum die-casting manufacturing techniques to provide the shockers with the highest strength, reliability, and coefficients of durability and longevity.

At Auto Die Cast (India), we know that safe, reliable driving depends on superior quality parts, and among the most important is the brake drum. With a brake drum it is possible to have effective and stable braking, with which the driver can control. As one of the premier brake drum suppliers, our quality control program meets or exceeds standards based on casting size. Our goal is to offer superior products, ensuring every vehicle travels safely and comfortably. With rich manufacturing experience and a comprehensive understanding of automobile needs, Auto Die Cast (India) has become one of the leading manufacturers of brake drums in India. Each item is specially engineered to make certain that it provides safety, performance, and durability for commercial purposes, while providing the same characteristics for personal use.

Choosing the right Aluminium Die Casting Component is a crucial factor for any manufacturing plant. Whether it is the automotive sector, electrical sector, engineering sector, or heavy machinery sector, the quality of the component has a major impact on the performance and price of the component. Unnecessary failures can be caused due to improper selection of the component.

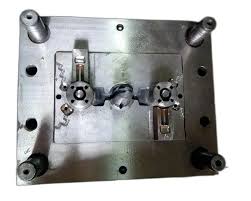

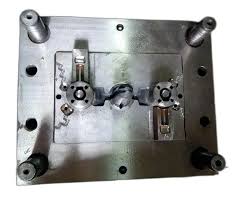

Manufacturers in the automobile sector today are increasing their efforts towards precision, durability, and production efficiency as they are in a very competitive environment. The need for lighter vehicles, stronger parts, and the ability to consistently operate at a certain level have necessitated advanced casting technology to be at the core of the current manufacturing processes. High Pressure Die Casting Mold for Automotive Industry is one of the most efficient solution-supporting transformations that help manufacture high-quality parts with incredible precision. Automakers depend on advanced mold design and engineering techniques to guarantee that each part complies with strict industry regulations while remaining cost-effective and durable.

The manufacturing industry is changing fast and automotive and industrial industries are embracing new technologies in order to remain competitive. Die Casting Mold Design is one of the most crucial spheres of change since it is now oriented on precision, speed and long-term durability. The contemporary manufacturers are not only increasing the production efficiency but also the product quality by advancing the engineering solutions. As more companies require lightweight and complex metal items, firms are beginning to invest in the development of high-tech molds formulation techniques that are in line with the global production trends. Major companies like Auto Die Cast (India) are making a major contribution towards the introduction of next-generation methods that have been known to assist companies to attain stable and credible casting abilities.

When it comes to electric rickshaws, safety is critical. Electric rickshaws operate on the streets every day in highly busy areas with uneven roads and a lot of people. A small mechanical failure could create a large amount of discomfort or destruction or cause an accident. Electric rickshaws have five ride support parts, of which the E Rickshaw Shockers are one and are primarily responsible for both passenger comfort and ride stability, as well as for controlling the operation of the electric rickshaw. Authentic electric rickshaw shockers provide safety and reliability in addition to performance.

Copyright © 2026 Auto Die Cast (India)